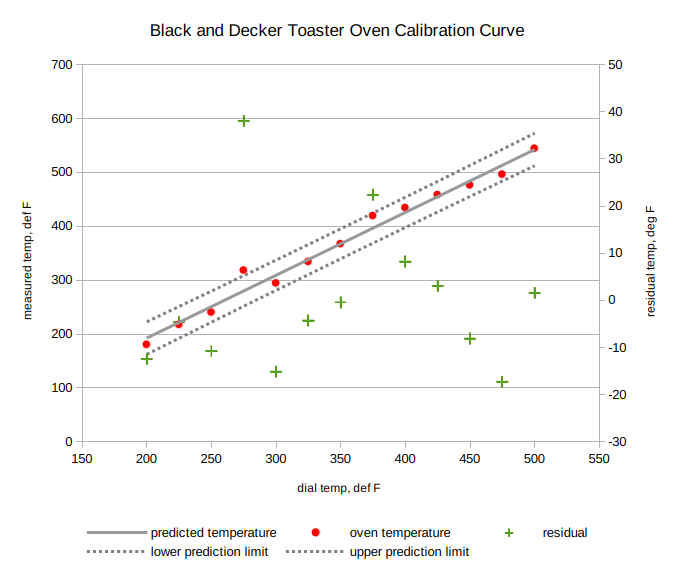

Black & Decker Toast-R-Oven / Broiler Calibration Curve

I got an old toaster oven for curing epoxy, e.g. Cactus Juice. The resin cures at 190-200° F (87-93° C), see manufacturer instructions, which is a relatively small window. I'm pretty sure that the curing process isn't all that sensitive to imprecision in this temperature, but I figured I'd calibrate the temperature gauge on the oven just in case. So below is a calibration build from setting the dial, waiting for it to equilibrate, then measuring the same spot on the inside of the oven. I used a laser thermometer, but an analog oven thermometer would probable be better as the laster is pretty sensitive to the reflectance of the surface you hit. Anyways, it's good enough.

Chart

Coefficients for linear regression (r^2=0.98):

| coefficient | value |

| m | 1.16 |

| b | -40.84 |

Raw Data:

| dial temp | oven temperature | predicted | residual |

| 200 | 180 | 192.47 | -12.47 |

| 225 | 217 | 221.63 | -4.63 |

| 250 | 240 | 250.80 | -10.80 |

| 275 | 318 | 279.96 | 38.03 |

| 300 | 294 | 309.13 | -15.13 |

| 325 | 334 | 338.29 | -4.29 |

| 350 | 367 | 367.46 | -0.46 |

| 375 | 419 | 396.62 | 22.37 |

| 400 | 434 | 425.79 | 8.20 |

| 425 | 458 | 454.95 | 3.04 |

| 450 | 476 | 484.12 | -8.12 |

| 475 | 496 | 513.28 | -17.28 |

| 500 | 544 | 542.45 | 1.54 |

Tags: rock-prep, workflows, calibration